Chinook salmon arriving at Big Bar Slide in the next few weeks won’t be able to swim past rapids or negotiate their way through a nature-like fishway constructed along the canyon wall.

Instead, the first fish migrating up the Fraser River after a year of slide remediation efforts will probably have to be transported over a waterfall by a “fish pump,” a pneumatic tube system used for the first time in Canada.

DFO has known since last winter that it would be impossible to remove enough slide debris from the river channel to permit natural salmon passage in 2020. The sheer volume of debris from the rock slide south of Lillooet — 75,000 to 80,000 cubic metres of boulders constricting the flow of B.C.’s most important salmon pathway — was too great to clear in a limited time frame. That grew apparent after contractor Peter Kiewit Sons ULC began blasting and channel clearing last winter during seasonally low water conditions.

“In February, our worst fears were confirmed,” said Gwil Roberts, DFO’s slide response director.

They would need more time, at least another year to complete channel remediation work. Only 10 to 15 percent of the rock has been removed so far.

Rock removal came to an end around Easter with the final blasting of what’s known as the East Toe, Roberts said. They were also able to widen the channel. River levels then spiked in late April due to an Interior warm spell that halted work for a couple of days. A higher than average snow pack in the Interior hasn’t helped.

“We’re at the mercy of the elements to some extent,” he said.

The first migrating salmon to arrive will be spring, due in late May, bound for natal waters in the upper Fraser basin. Mindful of the run timing, about 40 workers are on site. They’ve worked continuously through the COVID-19 pandemic and Easter holiday to bring short-term mitigation projects on stream in time.

Three mitigation measures are designed to provide salmon and steelhead passage this year, starting with a nature-like fishway that will allow them to swim upriver if the flow rate is between 1,700 and 3,200 cubic metres per second. When the river exceeds that rate, as it typically does in spring and early summer, a commercial fish pump called the Whooshh Passage Portal becomes the backup system. Two pneumatic tubes to send fish 160 metres upriver should be operating by late May. Expanding to six in early June, they will probably be needed until late July when the river flow drops and the fishway becomes viable.

Seattle’s Whooshh Innovations adapted fruit transport tubes a decade ago as an innovative means to transport fish past dams and other river obstacles. About two dozen of the systems have been used on waterways in the U.S. and Europe.

“More than anything, we see it from a fish perspective, knowing the fish don’t have time anymore,” said Vince Bryan III, founder and CEO. In most cases where the technology is applied, obstacles to anadromous fish are man-made, such as dams and low water due to irrigation demands, he noted. “How do you prevent losing runs year after year?”

Research has shown that fish are not stressed by the brief transit through the tubes and that they fare better than in fish ladders, conserving energy reserves essential to their migratory journey and successful spawning. They’re also healthier for not being handled in automated-feed systems such as this one, a system first used in 2017, he said.

Some feel the pneumatic system should have been deployed from the outset at Big Bar Slide to deal with the disastrous impasse after it was discovered last June. That was felt to be too risky since it would have required a barge in the turbulent river in the absence of an access road.

“A huge part of the effort this past winter was getting the access road built to the slide area. Kiewit has put in an amazing effort to build that road,” said Roberts.

Crews are building a fish ladder, stacking more than 500 interlocking concrete blocks, designed to direct salmon to a holding area for either “tubing” or trucking, Roberts said. Trapping and trucking salmon four kilometres upriver is the least preferred method but offers better prospects for success than last summer, when beach seining and helicopter buckets were also hurried into action.

“Last year, when the slide was discovered in late June, the fish had already been at the slide for well over a month,” Roberts said. “The fish were tired, worn out and injured by poor conditions.”

With the limited winter window for channel work, how much longer will it take before fish swim past Big Bar Slide on their own?

The hope is that channel clearing can be completed next winter, said Roberts, who considers himself an optimist.

“I hazard to guess,” he added. “Again, we’re hoping for the best. We’ll resolve this as quickly as possible but that’s still unknown.”

In the meantime, fish migration and hydrological monitoring will be done through the summer.

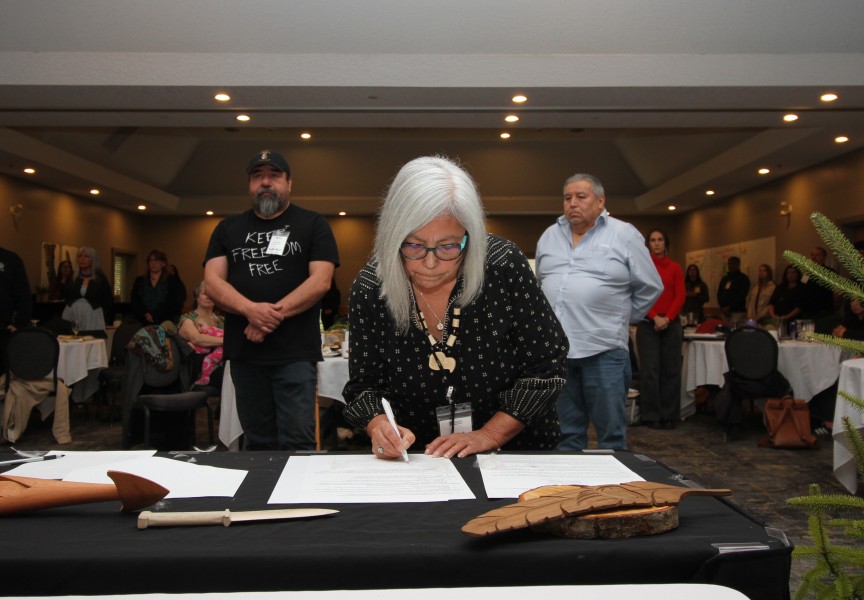

A tri-partite committee comprised of First Nation community and agency representatives, DFO and the provincial government has project oversight. Job opportunities will be available, ensuring healthy passage for fish.

“We intend to employ a sizeable contingent of First Nation workers for transport and hatchery work,” Roberts said. “We rely on their technical know-how and proficiency for transportation and enhancement.”

The slide is believed to have been triggered by seismic activity in November 2018 and blocked the river because flow was unusually low at the time.

Roberts said there is also speculation that migrating fish had difficulty passing those same rapids for some time, well before the slide.

“This has been a constricted point and the flows have been high for many freshets,” he said.

Although costly, the remediation project offers an opportunity to improve fish passage in the long term, he added.